What are the Latest DC Resistor Equipment Component Purchasing Models?

I. Introduction

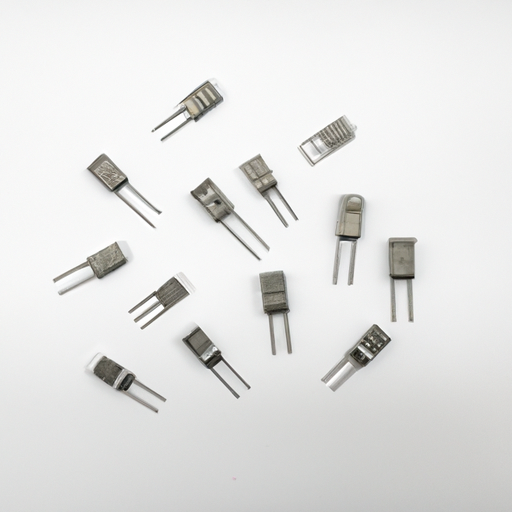

In the world of electrical and electronic applications, DC resistor equipment components play a crucial role. These components are essential for controlling current flow, managing voltage levels, and ensuring the stability of circuits. As technology evolves, so too do the methods by which these components are purchased. Understanding the latest purchasing models is vital for manufacturers, engineers, and procurement professionals looking to optimize their supply chains and meet the demands of a rapidly changing market.

II. Evolution of Purchasing Models

A. Historical Context

Historically, purchasing methods for DC resistor components were straightforward and often involved direct transactions between manufacturers and suppliers. Buyers would rely on established relationships and face-to-face negotiations to secure the components they needed. However, as the industry has grown and diversified, these traditional methods have given way to more modern approaches.

B. Factors Influencing Change

Several factors have influenced this shift in purchasing models. Technological advancements have made it easier for companies to connect with suppliers globally, while market demand and consumer behavior have pushed for more efficient and flexible purchasing options. Additionally, global supply chain dynamics have necessitated a reevaluation of how components are sourced, leading to the adoption of new purchasing strategies.

III. Current Purchasing Models

A. Direct Purchasing

Direct purchasing remains a common model in the procurement of DC resistor components. This method involves buying directly from manufacturers, allowing for better control over pricing and quality. The process typically includes negotiating terms, placing orders, and managing logistics.

**Advantages:**

- Direct communication with manufacturers can lead to better pricing and terms.

- Greater control over quality and specifications.

**Disadvantages:**

- May require significant time and resources to manage relationships and logistics.

- Limited flexibility in terms of order quantities and delivery times.

B. Online Marketplaces

The rise of online marketplaces has transformed the way components are purchased. Platforms like Digi-Key, Mouser, and Alibaba have made it easier for buyers to find and compare products from various suppliers.

**Benefits of Online Purchasing:**

- Convenience and accessibility, allowing for 24/7 purchasing.

- A wider selection of products and suppliers, enabling better price comparisons.

**Challenges and Considerations:**

- Potential quality concerns, as not all suppliers may meet industry standards.

- The need for thorough research to ensure reliable sourcing.

C. Distributor Partnerships

Working with distributors has become a popular purchasing model for many companies. Distributors act as intermediaries between manufacturers and buyers, providing a range of services, including inventory management, logistics, and technical support.

**Benefits of Working with Distributors:**

- Access to a broader range of products and brands.

- Reduced lead times and improved inventory management.

**Case Studies of Successful Partnerships:**

Many companies have reported increased efficiency and cost savings by partnering with distributors who understand their specific needs and can provide tailored solutions.

D. Just-In-Time (JIT) Purchasing

The Just-In-Time (JIT) purchasing model focuses on minimizing inventory levels by ordering components only as they are needed. This approach can significantly reduce holding costs and improve cash flow.

**Impact on Inventory Management:**

- JIT purchasing requires precise forecasting and strong supplier relationships to ensure timely delivery.

- It can lead to increased efficiency and reduced waste in the supply chain.

**Real-World Applications in the Resistor Market:**

Many electronics manufacturers have adopted JIT purchasing to streamline their operations and respond quickly to market changes.

IV. Emerging Trends in Purchasing Models

A. E-commerce and Digital Transformation

The digital transformation of the purchasing landscape has been accelerated by the rise of e-commerce. Companies are increasingly turning to online platforms to source components, driven by the need for speed and efficiency.

**Impact of Digital Tools and Platforms:**

- Enhanced data analytics capabilities allow for better decision-making in procurement.

- Digital tools facilitate easier communication and collaboration between buyers and suppliers.

B. Sustainability and Ethical Sourcing

As consumers become more environmentally conscious, the importance of sustainability in purchasing practices has grown. Companies are now prioritizing ethical sourcing and sustainable practices in their procurement strategies.

**How Companies are Adapting to Consumer Preferences:**

- Many manufacturers are seeking suppliers who adhere to sustainable practices, such as using eco-friendly materials and reducing waste.

- Transparency in the supply chain is becoming a key factor in purchasing decisions.

C. Customization and Personalization

The demand for tailored solutions is on the rise, leading to innovations in custom resistor manufacturing. Companies are increasingly looking for suppliers who can provide customized components to meet specific application requirements.

**Innovations in Custom Resistor Manufacturing:**

- Advances in manufacturing technologies, such as 3D printing, are enabling more flexible production processes.

- Customization can lead to improved performance and efficiency in electronic applications.

V. Challenges in the Current Purchasing Landscape

A. Supply Chain Disruptions

Recent global events, such as the COVID-19 pandemic and geopolitical tensions, have highlighted vulnerabilities in supply chains. These disruptions can lead to delays and increased costs for companies relying on DC resistor components.

**Strategies for Mitigating Risks:**

- Diversifying suppliers and sourcing from multiple regions can help reduce dependency on a single source.

- Building strong relationships with suppliers can enhance communication and responsiveness during crises.

B. Quality Assurance and Standards

Ensuring the quality of resistor components is critical, as subpar products can lead to failures in electronic applications. Companies must navigate a complex landscape of industry standards and regulations.

**Importance of Quality in Resistor Components:**

- Rigorous testing and certification processes are essential to maintain high-quality standards.

- Companies must stay informed about evolving regulations and compliance requirements.

C. Cost Management

Balancing quality and cost is a constant challenge in the purchasing landscape. Companies must find ways to manage costs without compromising on the quality of components.

**Strategies for Cost-Effective Purchasing:**

- Leveraging bulk purchasing and long-term contracts can lead to cost savings.

- Regularly reviewing supplier performance and pricing can help identify opportunities for negotiation.

VI. Future Directions in Purchasing Models

A. Integration of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning into purchasing processes is set to revolutionize the industry. These technologies can enhance decision-making and streamline procurement operations.

**Predictive Analytics in Purchasing Decisions:**

- AI can analyze historical data to forecast demand and optimize inventory levels.

- Machine learning algorithms can identify patterns and trends, enabling more informed purchasing strategies.

B. Blockchain Technology

Blockchain technology has the potential to enhance transparency and traceability in the supply chain. By providing a secure and immutable record of transactions, blockchain can improve trust between buyers and suppliers.

**Potential Applications in Resistor Supply Chains:**

- Blockchain can facilitate real-time tracking of components, ensuring compliance with quality standards.

- It can also streamline payment processes and reduce fraud in procurement.

C. Collaborative Purchasing

Collaborative purchasing, often facilitated by Group Purchasing Organizations (GPOs), allows companies to pool their purchasing power to negotiate better terms and prices.

**Benefits of Group Purchasing Organizations (GPOs):**

- GPOs can leverage collective buying power to secure discounts and favorable terms.

- They can also provide access to a wider range of suppliers and products.

**Case Studies of Successful Collaborations:**

Many companies have reported significant cost savings and improved supplier relationships through collaborative purchasing initiatives.

VII. Conclusion

The landscape of DC resistor equipment component purchasing is evolving rapidly, driven by technological advancements, changing consumer preferences, and global supply chain dynamics. Companies must adapt to these changes by embracing new purchasing models, leveraging digital tools, and prioritizing sustainability and customization. By staying informed about emerging trends and challenges, businesses can optimize their procurement strategies and ensure a competitive edge in the market.

VIII. References

- Industry reports and white papers on purchasing models and trends.

- Relevant academic journals and articles discussing the evolution of procurement in the electronics industry.

- Case studies highlighting successful purchasing strategies in the resistor market.

In conclusion, the future of DC resistor equipment component purchasing is bright, with numerous opportunities for innovation and improvement. By embracing these changes, companies can position themselves for success in an increasingly complex and competitive landscape.

What are the Latest DC Resistor Equipment Component Purchasing Models?

I. Introduction

In the world of electrical and electronic applications, DC resistor equipment components play a crucial role. These components are essential for controlling current flow, managing voltage levels, and ensuring the stability of circuits. As technology evolves, so too do the methods by which these components are purchased. Understanding the latest purchasing models is vital for manufacturers, engineers, and procurement professionals looking to optimize their supply chains and meet the demands of a rapidly changing market.

II. Evolution of Purchasing Models

A. Historical Context

Historically, purchasing methods for DC resistor components were straightforward and often involved direct transactions between manufacturers and suppliers. Buyers would rely on established relationships and face-to-face negotiations to secure the components they needed. However, as the industry has grown and diversified, these traditional methods have given way to more modern approaches.

B. Factors Influencing Change

Several factors have influenced this shift in purchasing models. Technological advancements have made it easier for companies to connect with suppliers globally, while market demand and consumer behavior have pushed for more efficient and flexible purchasing options. Additionally, global supply chain dynamics have necessitated a reevaluation of how components are sourced, leading to the adoption of new purchasing strategies.

III. Current Purchasing Models

A. Direct Purchasing

Direct purchasing remains a common model in the procurement of DC resistor components. This method involves buying directly from manufacturers, allowing for better control over pricing and quality. The process typically includes negotiating terms, placing orders, and managing logistics.

**Advantages:**

- Direct communication with manufacturers can lead to better pricing and terms.

- Greater control over quality and specifications.

**Disadvantages:**

- May require significant time and resources to manage relationships and logistics.

- Limited flexibility in terms of order quantities and delivery times.

B. Online Marketplaces

The rise of online marketplaces has transformed the way components are purchased. Platforms like Digi-Key, Mouser, and Alibaba have made it easier for buyers to find and compare products from various suppliers.

**Benefits of Online Purchasing:**

- Convenience and accessibility, allowing for 24/7 purchasing.

- A wider selection of products and suppliers, enabling better price comparisons.

**Challenges and Considerations:**

- Potential quality concerns, as not all suppliers may meet industry standards.

- The need for thorough research to ensure reliable sourcing.

C. Distributor Partnerships

Working with distributors has become a popular purchasing model for many companies. Distributors act as intermediaries between manufacturers and buyers, providing a range of services, including inventory management, logistics, and technical support.

**Benefits of Working with Distributors:**

- Access to a broader range of products and brands.

- Reduced lead times and improved inventory management.

**Case Studies of Successful Partnerships:**

Many companies have reported increased efficiency and cost savings by partnering with distributors who understand their specific needs and can provide tailored solutions.

D. Just-In-Time (JIT) Purchasing

The Just-In-Time (JIT) purchasing model focuses on minimizing inventory levels by ordering components only as they are needed. This approach can significantly reduce holding costs and improve cash flow.

**Impact on Inventory Management:**

- JIT purchasing requires precise forecasting and strong supplier relationships to ensure timely delivery.

- It can lead to increased efficiency and reduced waste in the supply chain.

**Real-World Applications in the Resistor Market:**

Many electronics manufacturers have adopted JIT purchasing to streamline their operations and respond quickly to market changes.

IV. Emerging Trends in Purchasing Models

A. E-commerce and Digital Transformation

The digital transformation of the purchasing landscape has been accelerated by the rise of e-commerce. Companies are increasingly turning to online platforms to source components, driven by the need for speed and efficiency.

**Impact of Digital Tools and Platforms:**

- Enhanced data analytics capabilities allow for better decision-making in procurement.

- Digital tools facilitate easier communication and collaboration between buyers and suppliers.

B. Sustainability and Ethical Sourcing

As consumers become more environmentally conscious, the importance of sustainability in purchasing practices has grown. Companies are now prioritizing ethical sourcing and sustainable practices in their procurement strategies.

**How Companies are Adapting to Consumer Preferences:**

- Many manufacturers are seeking suppliers who adhere to sustainable practices, such as using eco-friendly materials and reducing waste.

- Transparency in the supply chain is becoming a key factor in purchasing decisions.

C. Customization and Personalization

The demand for tailored solutions is on the rise, leading to innovations in custom resistor manufacturing. Companies are increasingly looking for suppliers who can provide customized components to meet specific application requirements.

**Innovations in Custom Resistor Manufacturing:**

- Advances in manufacturing technologies, such as 3D printing, are enabling more flexible production processes.

- Customization can lead to improved performance and efficiency in electronic applications.

V. Challenges in the Current Purchasing Landscape

A. Supply Chain Disruptions

Recent global events, such as the COVID-19 pandemic and geopolitical tensions, have highlighted vulnerabilities in supply chains. These disruptions can lead to delays and increased costs for companies relying on DC resistor components.

**Strategies for Mitigating Risks:**

- Diversifying suppliers and sourcing from multiple regions can help reduce dependency on a single source.

- Building strong relationships with suppliers can enhance communication and responsiveness during crises.

B. Quality Assurance and Standards

Ensuring the quality of resistor components is critical, as subpar products can lead to failures in electronic applications. Companies must navigate a complex landscape of industry standards and regulations.

**Importance of Quality in Resistor Components:**

- Rigorous testing and certification processes are essential to maintain high-quality standards.

- Companies must stay informed about evolving regulations and compliance requirements.

C. Cost Management

Balancing quality and cost is a constant challenge in the purchasing landscape. Companies must find ways to manage costs without compromising on the quality of components.

**Strategies for Cost-Effective Purchasing:**

- Leveraging bulk purchasing and long-term contracts can lead to cost savings.

- Regularly reviewing supplier performance and pricing can help identify opportunities for negotiation.

VI. Future Directions in Purchasing Models

A. Integration of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning into purchasing processes is set to revolutionize the industry. These technologies can enhance decision-making and streamline procurement operations.

**Predictive Analytics in Purchasing Decisions:**

- AI can analyze historical data to forecast demand and optimize inventory levels.

- Machine learning algorithms can identify patterns and trends, enabling more informed purchasing strategies.

B. Blockchain Technology

Blockchain technology has the potential to enhance transparency and traceability in the supply chain. By providing a secure and immutable record of transactions, blockchain can improve trust between buyers and suppliers.

**Potential Applications in Resistor Supply Chains:**

- Blockchain can facilitate real-time tracking of components, ensuring compliance with quality standards.

- It can also streamline payment processes and reduce fraud in procurement.

C. Collaborative Purchasing

Collaborative purchasing, often facilitated by Group Purchasing Organizations (GPOs), allows companies to pool their purchasing power to negotiate better terms and prices.

**Benefits of Group Purchasing Organizations (GPOs):**

- GPOs can leverage collective buying power to secure discounts and favorable terms.

- They can also provide access to a wider range of suppliers and products.

**Case Studies of Successful Collaborations:**

Many companies have reported significant cost savings and improved supplier relationships through collaborative purchasing initiatives.

VII. Conclusion

The landscape of DC resistor equipment component purchasing is evolving rapidly, driven by technological advancements, changing consumer preferences, and global supply chain dynamics. Companies must adapt to these changes by embracing new purchasing models, leveraging digital tools, and prioritizing sustainability and customization. By staying informed about emerging trends and challenges, businesses can optimize their procurement strategies and ensure a competitive edge in the market.

VIII. References

- Industry reports and white papers on purchasing models and trends.

- Relevant academic journals and articles discussing the evolution of procurement in the electronics industry.

- Case studies highlighting successful purchasing strategies in the resistor market.

In conclusion, the future of DC resistor equipment component purchasing is bright, with numerous opportunities for innovation and improvement. By embracing these changes, companies can position themselves for success in an increasingly complex and competitive landscape.