What are the Advantages of Carbon Film Resistor Products?

I. Introduction

Resistors are fundamental components in electronic circuits, serving to limit current flow, divide voltages, and protect sensitive components. Among the various types of resistors available, carbon film resistors have gained popularity due to their unique properties and advantages. This article aims to explore the benefits of carbon film resistors, their composition, manufacturing processes, applications, and how they compare to other resistor types.

II. Composition and Manufacturing of Carbon Film Resistors

A. Materials Used in Carbon Film Resistors

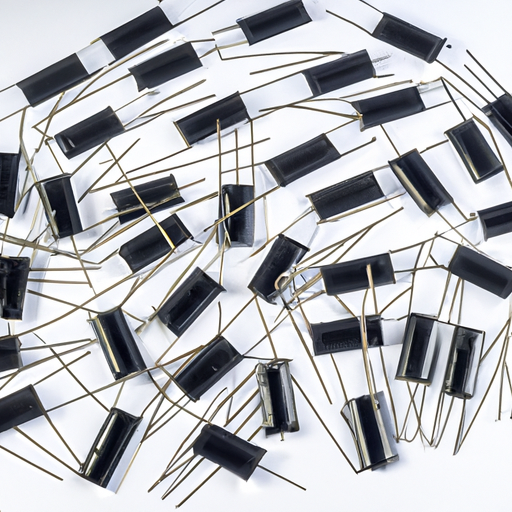

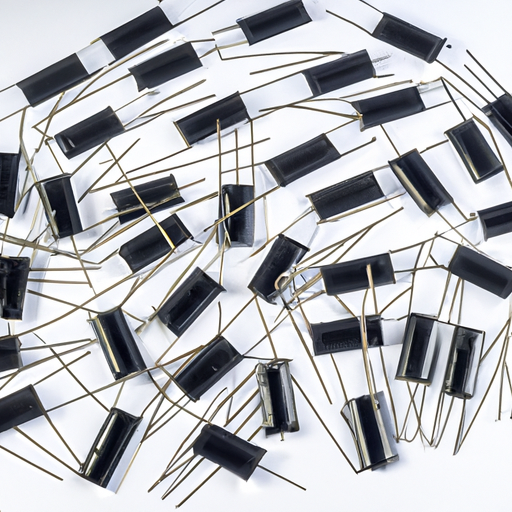

Carbon film resistors are made from a thin layer of carbon deposited onto a ceramic substrate. The carbon layer is typically mixed with a binding agent to enhance its stability and performance. The resistive value is determined by the thickness and length of the carbon film, which can be adjusted during the manufacturing process.

B. Manufacturing Process

The manufacturing of carbon film resistors involves several steps. Initially, a ceramic substrate is prepared, followed by the deposition of a carbon film using techniques such as vacuum deposition or sputtering. After the film is applied, it is etched to create the desired resistance value. Finally, the resistors are coated with a protective layer to enhance durability and reliability.

C. Comparison with Other Types of Resistors

When compared to other resistor types, such as metal film and wirewound resistors, carbon film resistors offer a balance of performance and cost. Metal film resistors are known for their precision and low noise, while wirewound resistors excel in high-power applications. However, carbon film resistors provide a good compromise, making them suitable for a wide range of applications.

III. Key Advantages of Carbon Film Resistors

A. Stability and Reliability

1. Temperature Coefficient

One of the significant advantages of carbon film resistors is their stability over a wide temperature range. They typically have a low temperature coefficient, meaning their resistance value changes minimally with temperature fluctuations. This stability is crucial in applications where consistent performance is required.

2. Long-term Performance

Carbon film resistors are designed for long-term reliability. They exhibit minimal drift in resistance over time, ensuring that electronic circuits maintain their intended performance throughout their lifespan.

B. Tolerance and Precision

1. Standard Tolerances

Carbon film resistors are available in various standard tolerances, typically ranging from 1% to 5%. This range makes them suitable for general-purpose applications where moderate precision is acceptable.

2. Precision Applications

For applications requiring higher precision, specialized carbon film resistors with tighter tolerances (as low as 0.1%) are available. These resistors are ideal for use in sensitive electronic devices, such as audio equipment and precision measurement instruments.

C. Noise Characteristics

1. Low Noise Levels

Carbon film resistors are known for their low noise characteristics, which is essential in audio and high-frequency applications. The noise generated by these resistors is significantly lower than that of carbon composition resistors, making them a preferred choice in high-fidelity audio circuits.

2. Impact on Circuit Performance

The low noise levels of carbon film resistors contribute to improved overall circuit performance. In applications where signal integrity is critical, such as telecommunications and medical devices, the use of carbon film resistors can enhance the quality of the output signal.

D. Cost-Effectiveness

1. Manufacturing Costs

Carbon film resistors are relatively inexpensive to manufacture compared to other high-precision resistors. This cost-effectiveness makes them an attractive option for manufacturers looking to balance performance and budget.

2. Economic Benefits for Bulk Purchases

For companies that require large quantities of resistors, carbon film resistors offer significant economic benefits. Bulk purchasing can lead to reduced costs per unit, making them a viable option for mass production in various industries.

E. Environmental Impact

1. Eco-Friendly Materials

The materials used in carbon film resistors are generally more environmentally friendly compared to those used in other resistor types. The carbon used is often derived from sustainable sources, reducing the overall environmental footprint of these components.

2. Recyclability

Carbon film resistors are also recyclable, which aligns with the growing trend towards sustainability in electronics manufacturing. As the industry moves towards greener practices, the recyclability of carbon film resistors makes them a more attractive option for environmentally conscious manufacturers.

IV. Applications of Carbon Film Resistors

Carbon film resistors are versatile components used in various applications, including:

A. Consumer Electronics

In consumer electronics, carbon film resistors are commonly found in devices such as televisions, audio equipment, and smartphones. Their low noise and stable performance make them ideal for these applications.

B. Industrial Equipment

Industrial equipment often requires reliable components that can withstand harsh conditions. Carbon film resistors are used in control systems, automation equipment, and power supplies due to their durability and stability.

C. Automotive Applications

In the automotive industry, carbon film resistors are utilized in various electronic systems, including engine control units, infotainment systems, and safety features. Their reliability and performance are critical in ensuring the safety and efficiency of modern vehicles.

D. Medical Devices

Medical devices require high precision and reliability, making carbon film resistors a suitable choice. They are used in diagnostic equipment, monitoring devices, and therapeutic instruments, where consistent performance is essential.

E. Telecommunications

In telecommunications, carbon film resistors are employed in signal processing and transmission equipment. Their low noise characteristics and stability contribute to improved signal quality and reliability in communication systems.

V. Comparison with Other Resistor Types

A. Carbon Composition Resistors

Carbon composition resistors are older technology and are known for their high noise levels and poor temperature stability. While they are still used in some applications, carbon film resistors offer superior performance and reliability.

B. Metal Film Resistors

Metal film resistors provide higher precision and lower noise than carbon film resistors. However, they are generally more expensive, making carbon film resistors a more cost-effective option for many applications.

C. Wirewound Resistors

Wirewound resistors are ideal for high-power applications but can be bulkier and more expensive. Carbon film resistors, on the other hand, offer a compact size and are suitable for a broader range of applications.

D. Summary of Advantages and Disadvantages

In summary, carbon film resistors strike a balance between performance, cost, and versatility. While they may not match the precision of metal film resistors or the power handling of wirewound resistors, their overall advantages make them a popular choice in many electronic applications.

VI. Future Trends in Carbon Film Resistor Technology

A. Innovations in Manufacturing

As technology advances, the manufacturing processes for carbon film resistors are becoming more efficient and precise. Innovations in deposition techniques and materials are expected to enhance the performance and reduce the costs of these resistors.

B. Emerging Applications

With the rise of new technologies, such as IoT devices and electric vehicles, the demand for reliable and cost-effective resistors is increasing. Carbon film resistors are well-positioned to meet these emerging needs due to their versatility and performance characteristics.

C. Sustainability Initiatives

As the electronics industry continues to focus on sustainability, carbon film resistors' eco-friendly materials and recyclability will become increasingly important. Manufacturers are likely to invest in sustainable practices to meet consumer demand for greener products.

VII. Conclusion

In conclusion, carbon film resistors offer numerous advantages that make them a preferred choice in various electronic applications. Their stability, reliability, low noise characteristics, cost-effectiveness, and environmental benefits position them as a versatile component in modern electronics. As technology continues to evolve, the role of carbon film resistors will remain significant, ensuring that they meet the demands of future innovations. When selecting resistors for specific applications, understanding the advantages of carbon film resistors can lead to better performance and reliability in electronic circuits.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications and Guidelines

This comprehensive overview highlights the key advantages of carbon film resistors, providing insights into their composition, applications, and future trends in technology. By understanding these benefits, manufacturers and engineers can make informed decisions when selecting resistors for their electronic designs.

What are the Advantages of Carbon Film Resistor Products?

I. Introduction

Resistors are fundamental components in electronic circuits, serving to limit current flow, divide voltages, and protect sensitive components. Among the various types of resistors available, carbon film resistors have gained popularity due to their unique properties and advantages. This article aims to explore the benefits of carbon film resistors, their composition, manufacturing processes, applications, and how they compare to other resistor types.

II. Composition and Manufacturing of Carbon Film Resistors

A. Materials Used in Carbon Film Resistors

Carbon film resistors are made from a thin layer of carbon deposited onto a ceramic substrate. The carbon layer is typically mixed with a binding agent to enhance its stability and performance. The resistive value is determined by the thickness and length of the carbon film, which can be adjusted during the manufacturing process.

B. Manufacturing Process

The manufacturing of carbon film resistors involves several steps. Initially, a ceramic substrate is prepared, followed by the deposition of a carbon film using techniques such as vacuum deposition or sputtering. After the film is applied, it is etched to create the desired resistance value. Finally, the resistors are coated with a protective layer to enhance durability and reliability.

C. Comparison with Other Types of Resistors

When compared to other resistor types, such as metal film and wirewound resistors, carbon film resistors offer a balance of performance and cost. Metal film resistors are known for their precision and low noise, while wirewound resistors excel in high-power applications. However, carbon film resistors provide a good compromise, making them suitable for a wide range of applications.

III. Key Advantages of Carbon Film Resistors

A. Stability and Reliability

1. Temperature Coefficient

One of the significant advantages of carbon film resistors is their stability over a wide temperature range. They typically have a low temperature coefficient, meaning their resistance value changes minimally with temperature fluctuations. This stability is crucial in applications where consistent performance is required.

2. Long-term Performance

Carbon film resistors are designed for long-term reliability. They exhibit minimal drift in resistance over time, ensuring that electronic circuits maintain their intended performance throughout their lifespan.

B. Tolerance and Precision

1. Standard Tolerances

Carbon film resistors are available in various standard tolerances, typically ranging from 1% to 5%. This range makes them suitable for general-purpose applications where moderate precision is acceptable.

2. Precision Applications

For applications requiring higher precision, specialized carbon film resistors with tighter tolerances (as low as 0.1%) are available. These resistors are ideal for use in sensitive electronic devices, such as audio equipment and precision measurement instruments.

C. Noise Characteristics

1. Low Noise Levels

Carbon film resistors are known for their low noise characteristics, which is essential in audio and high-frequency applications. The noise generated by these resistors is significantly lower than that of carbon composition resistors, making them a preferred choice in high-fidelity audio circuits.

2. Impact on Circuit Performance

The low noise levels of carbon film resistors contribute to improved overall circuit performance. In applications where signal integrity is critical, such as telecommunications and medical devices, the use of carbon film resistors can enhance the quality of the output signal.

D. Cost-Effectiveness

1. Manufacturing Costs

Carbon film resistors are relatively inexpensive to manufacture compared to other high-precision resistors. This cost-effectiveness makes them an attractive option for manufacturers looking to balance performance and budget.

2. Economic Benefits for Bulk Purchases

For companies that require large quantities of resistors, carbon film resistors offer significant economic benefits. Bulk purchasing can lead to reduced costs per unit, making them a viable option for mass production in various industries.

E. Environmental Impact

1. Eco-Friendly Materials

The materials used in carbon film resistors are generally more environmentally friendly compared to those used in other resistor types. The carbon used is often derived from sustainable sources, reducing the overall environmental footprint of these components.

2. Recyclability

Carbon film resistors are also recyclable, which aligns with the growing trend towards sustainability in electronics manufacturing. As the industry moves towards greener practices, the recyclability of carbon film resistors makes them a more attractive option for environmentally conscious manufacturers.

IV. Applications of Carbon Film Resistors

Carbon film resistors are versatile components used in various applications, including:

A. Consumer Electronics

In consumer electronics, carbon film resistors are commonly found in devices such as televisions, audio equipment, and smartphones. Their low noise and stable performance make them ideal for these applications.

B. Industrial Equipment

Industrial equipment often requires reliable components that can withstand harsh conditions. Carbon film resistors are used in control systems, automation equipment, and power supplies due to their durability and stability.

C. Automotive Applications

In the automotive industry, carbon film resistors are utilized in various electronic systems, including engine control units, infotainment systems, and safety features. Their reliability and performance are critical in ensuring the safety and efficiency of modern vehicles.

D. Medical Devices

Medical devices require high precision and reliability, making carbon film resistors a suitable choice. They are used in diagnostic equipment, monitoring devices, and therapeutic instruments, where consistent performance is essential.

E. Telecommunications

In telecommunications, carbon film resistors are employed in signal processing and transmission equipment. Their low noise characteristics and stability contribute to improved signal quality and reliability in communication systems.

V. Comparison with Other Resistor Types

A. Carbon Composition Resistors

Carbon composition resistors are older technology and are known for their high noise levels and poor temperature stability. While they are still used in some applications, carbon film resistors offer superior performance and reliability.

B. Metal Film Resistors

Metal film resistors provide higher precision and lower noise than carbon film resistors. However, they are generally more expensive, making carbon film resistors a more cost-effective option for many applications.

C. Wirewound Resistors

Wirewound resistors are ideal for high-power applications but can be bulkier and more expensive. Carbon film resistors, on the other hand, offer a compact size and are suitable for a broader range of applications.

D. Summary of Advantages and Disadvantages

In summary, carbon film resistors strike a balance between performance, cost, and versatility. While they may not match the precision of metal film resistors or the power handling of wirewound resistors, their overall advantages make them a popular choice in many electronic applications.

VI. Future Trends in Carbon Film Resistor Technology

A. Innovations in Manufacturing

As technology advances, the manufacturing processes for carbon film resistors are becoming more efficient and precise. Innovations in deposition techniques and materials are expected to enhance the performance and reduce the costs of these resistors.

B. Emerging Applications

With the rise of new technologies, such as IoT devices and electric vehicles, the demand for reliable and cost-effective resistors is increasing. Carbon film resistors are well-positioned to meet these emerging needs due to their versatility and performance characteristics.

C. Sustainability Initiatives

As the electronics industry continues to focus on sustainability, carbon film resistors' eco-friendly materials and recyclability will become increasingly important. Manufacturers are likely to invest in sustainable practices to meet consumer demand for greener products.

VII. Conclusion

In conclusion, carbon film resistors offer numerous advantages that make them a preferred choice in various electronic applications. Their stability, reliability, low noise characteristics, cost-effectiveness, and environmental benefits position them as a versatile component in modern electronics. As technology continues to evolve, the role of carbon film resistors will remain significant, ensuring that they meet the demands of future innovations. When selecting resistors for specific applications, understanding the advantages of carbon film resistors can lead to better performance and reliability in electronic circuits.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications and Guidelines

This comprehensive overview highlights the key advantages of carbon film resistors, providing insights into their composition, applications, and future trends in technology. By understanding these benefits, manufacturers and engineers can make informed decisions when selecting resistors for their electronic designs.